Fan motor:Use special axial flow fan for cooling tower,the material is aluminum alloy blade,high air flow,low energy,low noise,long life,Streamlined high strength air duct guarantee the inlet and outlet evenly flow,minimize the energy consumption of fan,IP55,insulation grade is F.

Heat transferring coil:the heat transferring coil is the main part of cooling tower,is made of copper pipe or high quality steel pipe;Cooling medium through internal,Spray water outside to meet cooling requirement.

Steel pipe(G type) or Stainless steel(S type),Three time 2.5MPa high pressure test for classification and integration, to make sure the quality of welded junction is up to standard.All of pipe were treated with hot dip galvanizing through the high temperature molten bath,ensure pipe’s good performance.

Copper pipe(T type) use deoxidized T2 high quality copper pipe,The connection between the copper pipe and the elbow is welded by silver electrode,few solder point and high quality,the design pressure is 1.2MPa.

Casing: The casing use import aluminum zinc plate which is the one of best corrosion resistance for galvanized plate,working life is 3-6 times that of ordinary galvanized plate.Strong thermal resistance,elegant appearance.

Spray pump:High quality mechanical shaft seal without steering restriction,leak tightness,long life,special outdoor electrical machinery,import bearing with special configuration,guarantee pump running long term,small power,large flow,low noise,etc.

Drift eliminator:Use high quality PVC material,the structure could eliminate moisture from the air through change the airflow direction,ensure the drift rate under 0.001%;save water as much as possible,and ensure no pollution around tower,prevent LDB spread.

Fill:The fill is Ultra slim,0.3mm.There are drift and blade for each piece of fill.The blade and fill are joined together,restrict the flow of water interior.Inside blade reduce the trouble of running in winter.

Spray distribution system:Through large flow target nozzle to guarantee water spray evenly and continuous on the wall of coil,Allow water,fresh air and pipe medium to exchange adequately.

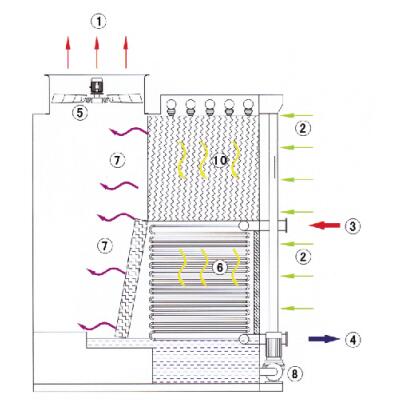

The working fluid(water,oil and other fluid) flows in the pipe,the outer wall of the pipe is covered by spray water,heat of the fluid is transmitted through the wall of pipe,forms saturated hot and humid air with water and air.Heat is discharged into the atmosphere by the fan,the water is blocked back to the basin for circulating spray.Spray water reduces water temperature through PVC radiator during circulation,fresh air and water flow in the same direction,Pipe mainly depends on the sensible heat conduction mode.The important characteristic of such operating principle is to restrain incrustation production of the outer wall of the coil pipe.

Flow Chart

1.Outlet of heat and humid air

2.Inlet of fresh air

3.Outlet of process fluid

4.Inlet of process fluid

5.Fan motor

6.Coil Pipe(cooper pipe or steel pipe)

7.Drift eliminator

8.Spray pump

9.Spray water system

10.PVC infill

Components:

1.Fan motor;2.Heat transferring coil;3.Casing;4.Spray pump;5.Drift eliminator;6.Electric incrustation cleaner(optional);7.Basin;8.Spray distribution system;9.control system;10.Infill.