The LKW series is an improved design based on the LKN counter-flow industrial cooling tower. In the actual operation of the cooling tower, there will be many factors working conditions. One of the working conditions is the high temperature sewage working condition. When the conventional cooling tower is operated under the condition of high temperature sewage, the deformation and blockage of the packing may occur. The cold effect of the cooling tower is seriously affected, resulting in a problem of insufficient cooling capacity of the cooling tower. Linko LKW series sewage cooling tower is specially designed for such working conditions. It improves the internal packing structure into FRP angle iron and special parts.While ensuring the heat dissipation area, the gap between the infill is increased, so that the particulate matter cannot be attached to the infill in a large amount. Get rid of the high water temperature and particulate matter on the cooling effect of the water tower.

1、Structural system

Tower metal component:The metal material constituting the tower body is made of high-strength and galvanizing treatment, which is light in weight and good in rigidity. The materials are in compliance with relevant national standards. Meanwhile,the parts are interchangeable, not only easy to assemble, but also good in stability. It can also be normal for a long time in a harsh environment.

The frame metal parts are hot-dip galvanized and have a thickness of 0.3-0.5mm, which has the advantages of corrosion resistance and oxidation resistance. All metal components are designed with reference to theoretical mechanics and material mechanics core design, with novel structure, firm connection, simple assembly and long service life.

Tower body surface components:These components are made of reinforced composite FRP, which has a uniform color tone, resistance to aging and fading.The surface gloss reaches 95-100 gloss units, and the surface adhesive is made of the world famous company - DSM's imported unsaturated polyester resin.The color type adopts imported "Japan Ink DIC" product, which contains U.V.S. light stabilizer, which can absorb ultraviolet light. The gel coat layer contains US imported light powder (DEGUSSA / AEROSIL 200 / 321293) with a thickness of 0.3-0.5mm.The thickness of FRP products is 4-10mm, and its bending strength is more than 250MPa detected by the National Fiberglass Products Quality Supervision and Inspection Center. The convex arc reinforced rib structure and modular design make the FRP products flexible and durable.The unique shape of the product blends with modern architecture.

2、 Heat exchange system

Flame retardant heat infill:

①The unique FRP angle iron design has good hydrophilicity, so that hot water flows through the surface of the packing to form a thin water film, and the water and air are more fully contacted, thereby enhancing the heat exchange performance and improving the cooling efficiency of the cooling tower.

②The flame retardant performance of the infill is good. The oxygen index of the tested infill is 38, which is much higher than the national standard requirement of ≥28.

③The water-filled packing is inverted with a “V” angle iron design and assembled in a tower in an installation mode, avoiding the accumulation of scale and resulting in insufficient cooling capacity;the large distance between the sheets ensures that the filler is not clogged, which reduces wind resistance and reduces the chance of biological derivation.

④This system not only has a good uniform air distribution effect, but also improves and stabilizes the heat exchange intensity of water and gas, and the precise positioning and equal spacing combination facilitates the formation of a large area of flowing water film with water flowing through the surface, facilitating water and gas exchange.

3、Unique water collecting structure:The use of high-quality PVC material thermoforming, in the domestic industry in the leading level, effectively remove the moisture in the hot and humid air and return to the tower, greatly reducing the loss of water, reducing the amount of water in the make-up water. LKN series cooling towers have a loss water rate of less than 0.001%.

4、Variable diameter grading nozzle:The sowing system uses the nozzles imported from the latest technology in the United States as the main component. The nozzle is made of high-quality modified P.P. injection molding, with no moving parts inside, corrosion resistance and aging resistance.The energy consumption is low during work, the large diameter is not easy to block and scale, and the disassembly, installation and maintenance are convenient.The unique variable-diameter design makes the cloth water continuous and uniform, forming a reliable “no hollow” umbrella-like “solid cone” sowing mode, no water and no dead angle.Hot water is evenly spread on the surface of the infill, effectively improving heat exchange efficiency.The nozzle is designed as an internal circular outer square structure,which is not easy to block, no need to clean, and reduce the workload of maintenance.

5、Drive System

Exhaust Fan:The fan is a low-speed space twisting forward tilting aluminum alloy cooling tower dedicated fan.The fan is made of high-quality aluminum alloy plate, and the fan is adjustable angle, which can meet the different requirements of customers on the air volume and other processes.The four-leaf type forward-sloping plate design makes each blade have small force, which has the advantages of low noise, large air volume, high efficiency, low power consumption and stable operation.The fan is strictly balanced and positioned before leaving the factory to ensure reliable performance.

Motor:Select a fully enclosed self-cooling low noise cooling tower dedicated motor.Protection class IP54, insulation class B,380(V)/3ψ/50(HZ).Small size, light weight, vertical installation, simple positioning, good starting performance, reliable operation and easy maintenance.In the hot and humid environment, the motor shaft waterproof rubber ring is specially designed、Junction box waterproof pad、the special drain hole of the seat ensures that the cooling tower motor is not wetted and the long-term operation is not damaged.

Motor Support:Adopting international advanced design concept, it is positioned on the tower steel structure frame, with few parts, convenient installation, good rigidity, small vibration, high stability, and is not affected by aging of glass fiber, and it is not easy to damage the transmission parts.

Speed Reducer:It is equipped with high-precision imported bearings, three-layer insurance oil seal, good waterproof performance, avoiding water vapor corrosion bearing.Disc-shaped steel seat support and cast iron frame pulley design, compact structure, with static balance check, stable operation, low noise.The unique inverted installation, convenient maintenance, noise and life are better than similar products, the reducer is designed with maintenance nozzles for daily maintenance.

Belt:It made of Japan's high-efficiency and powerful V-Belt and adopts advanced polymerized thermoplastic elastomer, it is wear-resistant, oil-resistant, water-resistant, aging-resistant, has good flexing performance, is not easy to stretch, has good running stability and long service life.

6、Attached system

Air Channel:The unique streamlined air inlet and precise blade air channel clearance enable the airflow to enter the air channel smoothly, avoiding the generation of eddy currents and reducing the energy consumption of the fan.A diffuser silencer is installed on the air channel to reduce the noise and reduce the wind speed of the cooling tower outlet, reduce the kinetic energy loss, save energy consumption, and reduce the hot and humid air flow and reflow.The air channel is modular in design and easy to assemble.

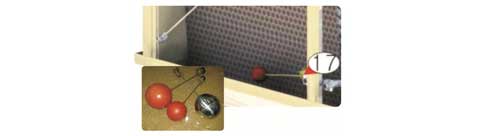

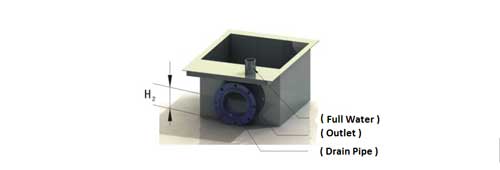

Water Supply:The water supply ball valve is installed on the inclined bottom basin to adjust the water supply and observe the water level of the bottom basin. The inclined bottom basin design is beneficial to the cleaning and drainage of the bottom basin.

Sale LKW Series Square Counter-Flow Industrial Cooling Tower