We supply ranges of water pumps for cooling towers with good quality and competitive price. We can help you to choose suitable pumps according to your requirements.

Standard for Pipeline Pump Products

ISO5199-1986 < Centrifugal Pump Technical Conditions 11 Categories > (International Standard)

JB/6878.2-93 < Pipeline Centrifugal Pump Technology > (Industry Standard)

GB/T13007-91 < Centrifugal Pump Efficiency >

GB/T13006-91 < Centrifugal Pump, Mixed Flow Pump & Axial Flow Pump >

GB3216-89 < Centrifugal Pump, Mixed Flow Pump, Axial Flow Pump & Vortex Pump Test Method >

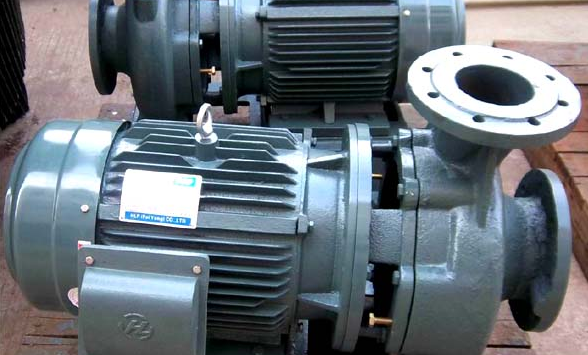

HL Series Horizontal Pipeline Pump

The Operating Principle of Feiyang Hailong HL 80-40 Pipeline Pump:

The water is thrown out by centrifugal force in physics of the pipeline centrifugal pump. The pump before starts working, the pump body and the water inlet pipe is filled with water, and entered the stable vacuum, then the motor power of the impeller becomes ?rotating quickly, the water pump is driven with the rapid rotation, when rotating to a certain speed, water will be under the centrifugal force to fly out, and the formation of the central region of the impeller vacuum. A large amount of water with the function of atmospheric pressure are pushed into the inlet pipe. The pipeline pump is such a cycle of work. In the use of pipeline pump, what we should pay attention to is: centrifugal pump must be filled with water to start before, otherwise the pump pipeline pump has suction may not be able to complete the work then leading to the pump body heat, vibration, water pump and other phenomenon, serious problems may also do some damage to the pipeline pump.

Working Conditions:

1, Suction pressure is less than 1.0MPa while maximum working pressure of the system no less than 1.6Mpa, the pump suction inlet pressure and the pump head is less than 1.6Mpa, while pump hydrostatic test pressure of 2.5MPa.

2, The ambient temperature is less than 40 ℃, and the relative humidity is less than 95%.

3, The liquid in transporting does not contain solid particles, or contains solid particle size can not exceed 0.1% of the unit volume, particle size is not greater than 0.2mm of the liquid.

Maintenance Attention in Use of Pipeline Pump:

1, The pipeline pump is best to use the ambient temperature of 40 ℃,when running the process, the maximum temperature of the bearing can not exceed 80 ℃.

2, The bearing lubricating oil should be replaced or supplemented. When adding lubricating oil, pay attention to observe the oil level and appropriate level must be in the oil standard center line.

3, Pipeline pump body water diversion plug screw, filling water (or lead paste).

4. Close the outlet pipe of the pipeline and the outlet pressure gauge and the imported vacuum gauge.

5, Move the pump motor, check the motor turning is right or not.

6, Start the pump motor, when the normal operation of the pipeline pump, open the outlet pressure gauge and imported vacuum pumps, as it shows the appropriate pressure, gradually open the valve, and check the motor loading.

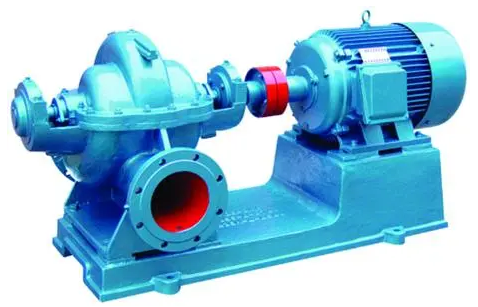

PY-GD Series Injection Pump

Fuel injection pump series injection cabinet seal type pump?is a single-stage single suction pipeline centrifugal pump, compared with the ordinary type centrifugal pipeline pump, fuel injection pump has good sealing performance, independence of the mechanical sealing oil chamber can effectively protect mechanical seal is not affected by the working fluid corrosion or particle wear, eliminate the damages of the mechanical seal leakage defects to the centrifugal pumps. So as to make its use more widely, not only can be used for refrigeration, air conditioning system, cooling tower, spraying garden, fire and other general water supply system, and more suitable for water curtain spray cabinet working environment of oil, ethylene glycol solution and other physical chemistry with small granular media.

HL Brand Series Horizontal Pipeline Pumps

Feiyang brand horizontal pipeline pump, technical personnel of the company pumps the United Nations experts selected the excellent hydraulic model and using is type centrifugal pump performance parameters, in general horizontal pipeline pump based on ingenious combination of design to made, and the use of temperature and medium in different alg basis derived from the application of hot water, high temperature resistant corrosion chemical pump,oil pump. The series of horizontal pipeline pump products has advantages as energy efficient, low noise, reliable performance, in line with the requirements of the latest national machinery Ministry JB/T53058-93 standard products according to ISO2858 international standard design and manufacture.

Main Use of Horizontal Pipeline Pump

1. HL brand horizontal water pump, for the transport of water, physical and chemical properties similar to water and other liquids used for industrial and urban water supply and drainage, pressurized water supply in high-rise buildings, garden irrigation, fire booster, long-range transport, HVAC refrigeration cycle, bathroom and other warm cold water circulation pressurization and supporting equipment, using the temperature T is ≤ 80℃.

2. HL brand horizontal hot water pump, widely used in metallurgy, chemical industry, textile, papermaking, hotels, hotels, and other hot water boiler pressurized circulating transport and urban heating system, alwr type using the temperature T is ≤ 120 ℃.

3. HL brand horizontal chemical pump, for conveying solid particles, with corrosive. Viscosity similar to liquid water, used in petroleum, chemical industry, metallurgy, electric power, papermaking, food, pharmaceuticals, synthetic fiber and other departments, using temperature for - 20 ℃ to 120 ℃.

4. HL brand horizontal pipeline oil pump, for the transport of gasoline, kerosene, diesel and other oil products, or flammable, explosive liquid, is transported medium temperature is - 20 to 120 ℃.

5. HL type horizontal stainless steel explosion-proof chemical centrifugal pump is applicable to transport inflammable chemical liquids.

6. HL horizontal low speed pump to meet the requirements of environmental noise occasions with low temperature T ≤ 120 ℃.

The Working Conditions of the HL Brand Horizontal Pipeline Pump

1. Suction pressure is less than or equal to 1.0 MPa, or pump system maximum working pressure ≤1.6Mpa, namely, inhalation of outlet pressure and pump head is ≤ 1.6Mpa, pump the hydrostatic test pressure is ≤ 2.5MPa, when ordering please specify the system working pressure. Pump system pressure greater than 1.6Mpa should be separately in order to be proposed, ?in the manufacture of pump flow and connection part of a steel material.

2 Ambient temperature < 40 ℃, relative humidity < 40%.

3 The transport media is not more than 0.1 of the unit volume, and the particle size is less than 0.2mm.

Note: if the medium is with small particles, please note in order to manufacturers to use wear-resistant mechanical seal.

Special Points

Stable Operation:absolute concentricity of pump shaft and impeller with excellent static and dynamic balance, to ensure smooth operation, no vibration.

No Leakage:hard alloy seal with different materials ensure the transportation of different medias without leakage.

Low Noise:pumps under the support of ?two low noise bearings, can keep running smoothly, ?without other noise besides the weak noise of the motor.

Low Fault Rate:simple and reasonable structure, the key part of the pumps asopt international first-class quality support, the whole machine working time is greatly improved.

Easy Maintenance:Simple and convenient to replace seal and bearing, .

Occupation Less Area:Outlet can be designed to left, right, up three directions, to facilitate the installation of pipeline layout, saving space.